OUCC Proceedings 11 (1983)Corrosion for Cavers II: Corrosion of Alloy Karabiners |

OUCC Proceedings 11 Contents |

Andy Riley

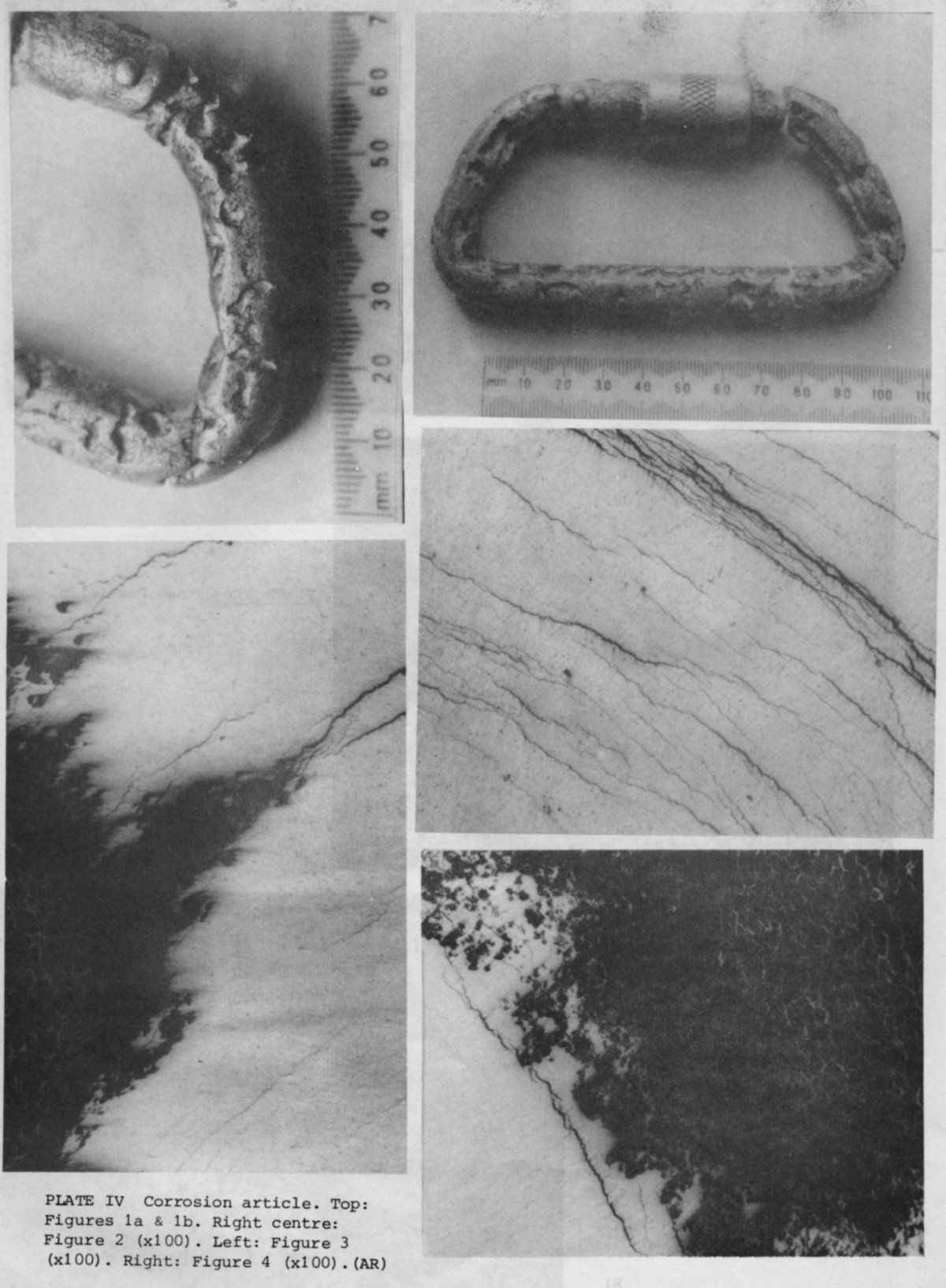

During a caving trip down Swinsto Hole, Kingsdale, N Yorkshire, a heavily pitted karabiner was found at the bottom of the 20 foot pitch lying under 0. 5 m of water in the gravel bed (Figures la and b).

The whole of the body of the karabiner was covered in pits several millimetres wide and deep. At the bottoms of the pits was a white, insoluble deposit. Only the screw-up gate was unaffected by corrosion. The unattacked parts of the surface did not show any more abrasion damage than would be expected to be caused by normal caving use.

A section

was made across the backbone of the karabiner which was hot-mounted in perspex

and polished to a 1 micron finish. Under optical examination, the entire section

was found to be full of cracks. This unexpected discovery led us to make further

investigations into the nature and origin of the cracks.

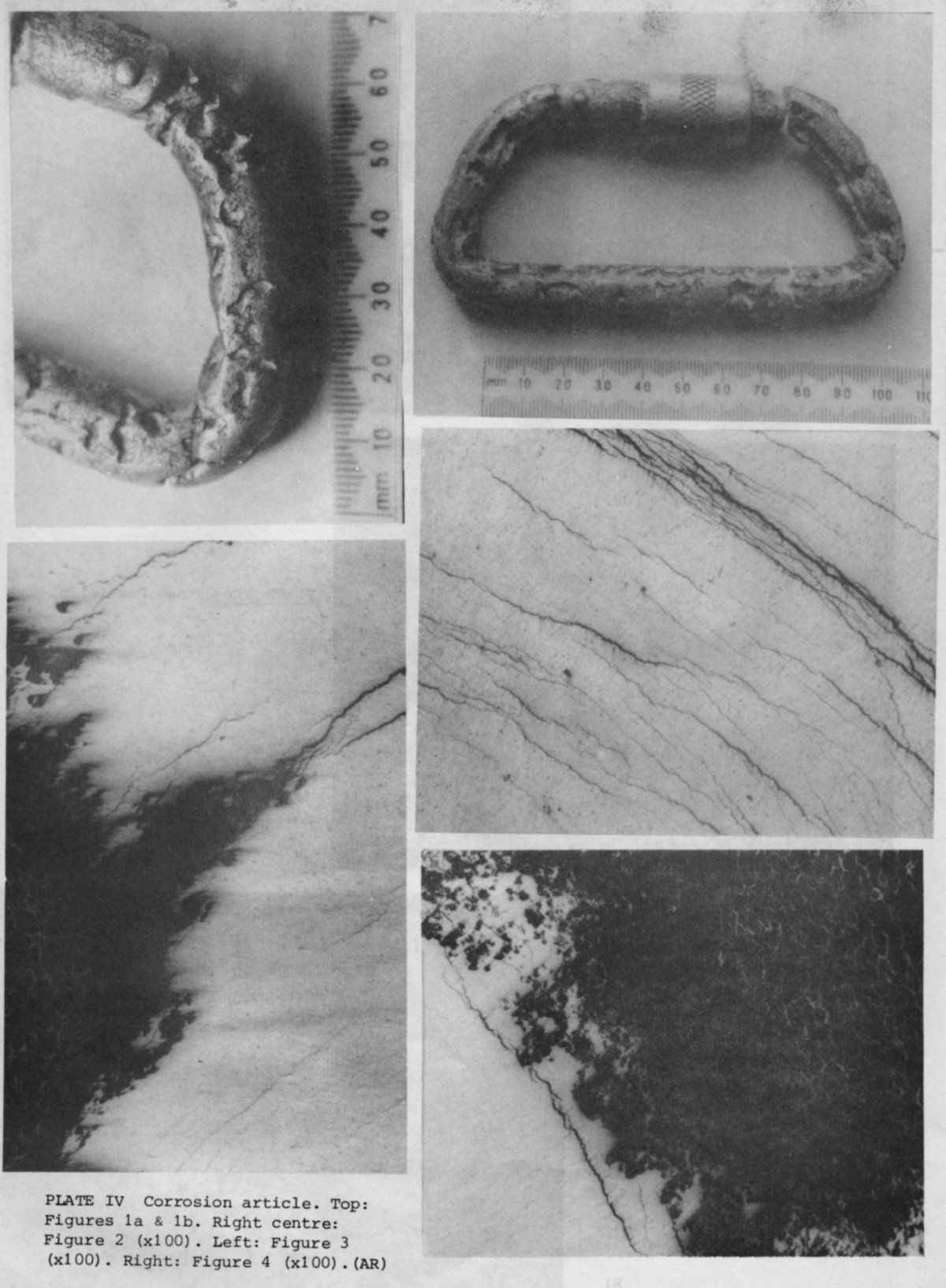

Under low

power observation, all the cracks were seen to run in circles, concentric with

the outer circumference of the section. The cracks were extremely numerous,

branched and finely divided (Figure 2). They seemed to be evenly distributed

throughout the whole section and were not located primarily at the surface. The

bases of some of the pits were examined. There was a definite orientation

dependence of the cracks to the base of the pits. In many of the pits, the

cracks were seen to emerge at the bottom (Figure 3), the pit growth direction

lying parallel to the crack direction. In other pits, the crack direction was

perpendicular to the direction of pit growth (Figure 4) and had not yet reached

the surface. All the pits had a deposit at their base. The aluminium metal at

the base of the pits showed signs of extensive corrosion attack and was very

spongy and porous in nature.

The

composition of the karabiner was unknown, but was determined by electron

microprobe analysis to be an Al-Zn-Mg-Cu alloy (see Table 1). An analysis of the

deposit in the base of the pits was attempted using energy dispersive analysis

(see Table 2). Wavelength dispersive analysis would have been superior but was

unavailable at the time of writing. The deposit was predominantly composed of

aluminium oxide.

Discussion of observations

The

chemical analysis suggests that the karabiner is a high-strength Al-Zn-Mg alloy.

Shreir (1976) suggests that these alloys have a high risk of suffering

stress-corrosion cracking which can be accelerated by incorrect heat treatment.

It seems likely that the surface pitting was probably initiated by the emergence

or interaction of the internal cracks with the surface. Once pitting has been

initiated, the pits grow unhindered by external effects or microstructure. This

is because pits generate an acid environment at their base which prevents

reformation of the passive film on the exposed aluminium surface (Robinson,

1960) and therefore corrosion proceeds rapidly. Impurities in the water can

assist in the initiation and propagation of pits - a combination of carbonates,

chlorides and copper ions can be very damaging (Davies, 1959). In hard water, as

little as 0.02 ppm of these ions can initiate pits (Porter and Hodder, 1953,

Rowe and Walker, 1961).

The

orientation of the cracks in the section strongly suggests that the

microstructure is exerting a major influence on their growth direction. The very

fine branched nature of the cracks suggests that they are intergranular.

Unfortunately, I was not able to etch up the grain boundaries in order to

demonstrate this. Exfoliation corrosion is a well-known phenomenon in high

strength aluminium alloys. Robinson has examined the effect of elongated grain

structure and heat treatment on the formation of surface blisters (Robinson,

1982). It seems likely that an elongated grain structure is formed in the alloy

karabiner during manufacture as it is extruded and that this initiates surface

and filiform attack. Grain boundary attack then causes the production of

corrosion products, creating large stresses at the grain boundary which force up

grains at the surface to create blisters. If these blisters reach a certain

size, a pit will form and pitting corrosion will dominate.

Conclusion

Grain

boundary attack has probably occurred because of precipitation and segregation

of alloying elements at grain boundaries during heat treatment. Exfoliation

corrosion produced blisters on the surface which in turn caused deep and severe

pitting. The intergranular attack and pitting in this karabiner has become

apparent due to its immersion for an unknown time in cave water which might be

expected to contain the necessary impurities for this kind of corrosive attack.

It would be interesting to know how long it would take for such attack to occur

and whether such slight attack which may occur during normal caving use has any

effect on the strength of the karabiner.

References

Davies, D.E., 1959. Pitting of aluminium in synthetic

waters. J. appl. Chem.

9, 651-660.

Porter, F. C. and Hadden, S.E., 1953. Corrosion of

aluminium alloys in supply waters. J. appl. Chem. 3,

385-409.

Robinson, F.P.A., 1960. Pitting corrosion - cause,

effect, detection and prevention. Corros.

Techno1. 7, 237-239, 266.

Robinson, M.J., 1982. Mathematical modelling of

exfoliation corrosion in high strength aluminium alloys.

Corros. Sci. 22, 775-790.

Rowe, L. C. and Walker, M.S., 1961. Effect of mineral

impurities in water on the corrosion of aluminium and steel.

Corrosion 17, 353t-356t.

Shreir, L.L., 1976.

Corrosion. Butterworth, London, 2 vols., 2nd edn.

Table

1.

Electron microprobe analysis

of karabiner alloy

composition

Standardless EDS analysis

(ZAF corrections

via magic V)

|

Element & line |

Weight % |

Atomic % |

Precision 3 sigma |

K-ratio |

Iter |

|

Al Ka |

92.54 |

6.77 |

1. 18 |

0.9279 |

|

|

Cu Ka |

1.11 |

0.49 |

0.34 |

0.0108 |

|

|

Zn Ka |

6.35 |

2.74 |

0.91 |

0.0613 |

6 |

+ ca. 1% Mg

Table 2. Electron microprobe analysis of

pit deposit composition

Standardless EDS analysis (ZAF corrections via magic

V)

|

Element & line |

K-ratio |

Weight % |

Precision 3 sigma |

Oxide formula |

Oxide % |

|

Al Ka

|

0.6654

|

37.40

|

1.10

|

A12O3

|

70.66

|

|

Si Ka |

0.0511 |

6.20 |

0.68 |

SiO2 |

13.27 |

|

S Ka |

0.0075 |

0.58 |

0.17 |

SO3 |

1.44 |

|

Ca Ka |

0.0168 |

0.77 |

0.18 |

CaO |

1.08 |

|

Fe Ka |

0.0358 |

1.42 |

0.36 |

FeO |

1.83 |

|

Cu Ka |

0. 1418 |

5.95 |

0.99 |

CuO |

7.45 |

|

Zn Ka |

0.0817 |

3.42 |

0.82 |

ZnO |

4.26 |

|

O* |

|

44.25 |

|

|

|

* - determined by stoichiometry